3D Printer

FlashForge Finder (from Sven's email)

I have set up one of the new 3D printers today (the red one). It is a FlashForge Finder.

The 3D printing workflow is as follows:

Design or download the files for a part (in .stl format). A good place to start is Thingiverse, it has thousands of projects that people have uploaded. You can get .stl files for the projects and send them to the printer with the FlashForge software.

Open it with a slicer and generate the code for the printer. The slicer opens the file generated by the CAD tool and converts it to command that the printer understands (3D printers understand something called g-code). One of the best ones is Simplify3D, but it is expensive. The free software for the Finder (FlashPrint) does a good job too.

Slic3r is Free, works on Windows/OSX/Linux, and works very well with the right settings. (Use "RepRap (Marlin/Sprinter/Repetier) as the G-code flavor and set it to a rectangular bed 140x140 with the origin at (70,70).)

Upload the file to the printer. This can be done with a USB drive (on the right side of the printer), or via WiFi from FlashPrint. The printer has its own WiFi network called FinderCHS: connect to that network, open the software and start the print.

It is really quite simple once you have done it once.

If you are interested in playing with it, you can download the software and the manual here (Finder):

Finder Manual as PDF. You can connect over WiFi: FinderCHS.

FlashForge Download Page for the FlashPrint software.

Please use only PLA or PETG (my favorite at the moment), as it has no heated bed and you can only print up to 235 degrees.

A good first thing to print is Marvin.

I hung up some white PLA. I was able to print something easily using the Flashforge software. I have some white board crudely set-up on top of the machine to stop the PLA from getting tangled in a contact switch, which would shut the machine down. Travis pointed out that PLA ages and soaks up moisture, making it not work as well as it should. The PLA is old, so I think everyone should make something before it's totally no good :) -- Max

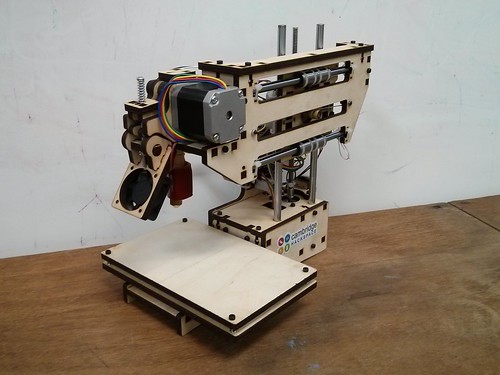

**Printrbot Simple 3D printer ** 1. Create a 3d model and export it in STL format 2. Import this into Repetier Host 3. Slice the models into thin slices and compute a path for printer head 4. Check the created g-code for errors 5. Send the g-code to the printer

Some additional tips and tricks (contact JAG for details:)

- Seal up the PLA in a bag when not in use -- if it gets too much water from the air it will get brittle

- Make sure you use the little white insert to guide the PLA into the extruder -- it helps to keep the filamenbt in the middle of the extrusion gear and ensures the best accuracy.

- Make a nice flat bed of 3M painters tape for your prints -- make sure each pass doesn't overlap

- Configure Repetier and slicer for a bed size of 100mm by 100m, nozzle width of 0.4mm, 200C

- Be careful of the Z limit switch -- the wires in the back are loose and if they get in the way the machine will not find its Z home position and lots of belt twisting will result

- The default EEPROM settings in the Marlin firmware (https://github.com/ErikZalm/Marlin) tell the printer how much steps of each motor are needed for each direction. The defaults are probably OK, but I actually use "M92 X110.00 Y110.00 Z2020.00 E98.00" (Tested with a micrometer in June 2014)

- To load PLA, the hot end must be hot. Plug in everything and click "set temperature" to 200 degrees. Wait until it gets warm and then loosen the fan assembly and manually feed the PLA down into the hot end extruding chamber until some starts to squirt out the bottom. Then replace the fan assembly carefully to provide tension against the extrusion gear.

- To remove items from the bed, use the chisel

Last edited by Richard at 02:50pm on 21st of February 2017